Abaqus Welding Interface Cracked Download Filme Corrente Do Bem Dublado Avi Virtua Striker 4 Dolphin Download For Pc WBS Chart Pro 4.4 The last serial number for this program was added to our data base on June 8, 2016 583 visitors told us the serial is good, 208 guys said the number is bad s/n: 893-073. To see full numbers without asterisks. The finite element analysis software Abaqus with the plug-in Abaqus Welding Interface (AWI) was used to simulate the welding process. The as-welded component was subjected to the hot-dip galvanizing process through a thermal simulation specified using an Abaqus user-subroutine. The parameters of the.

Abstract:

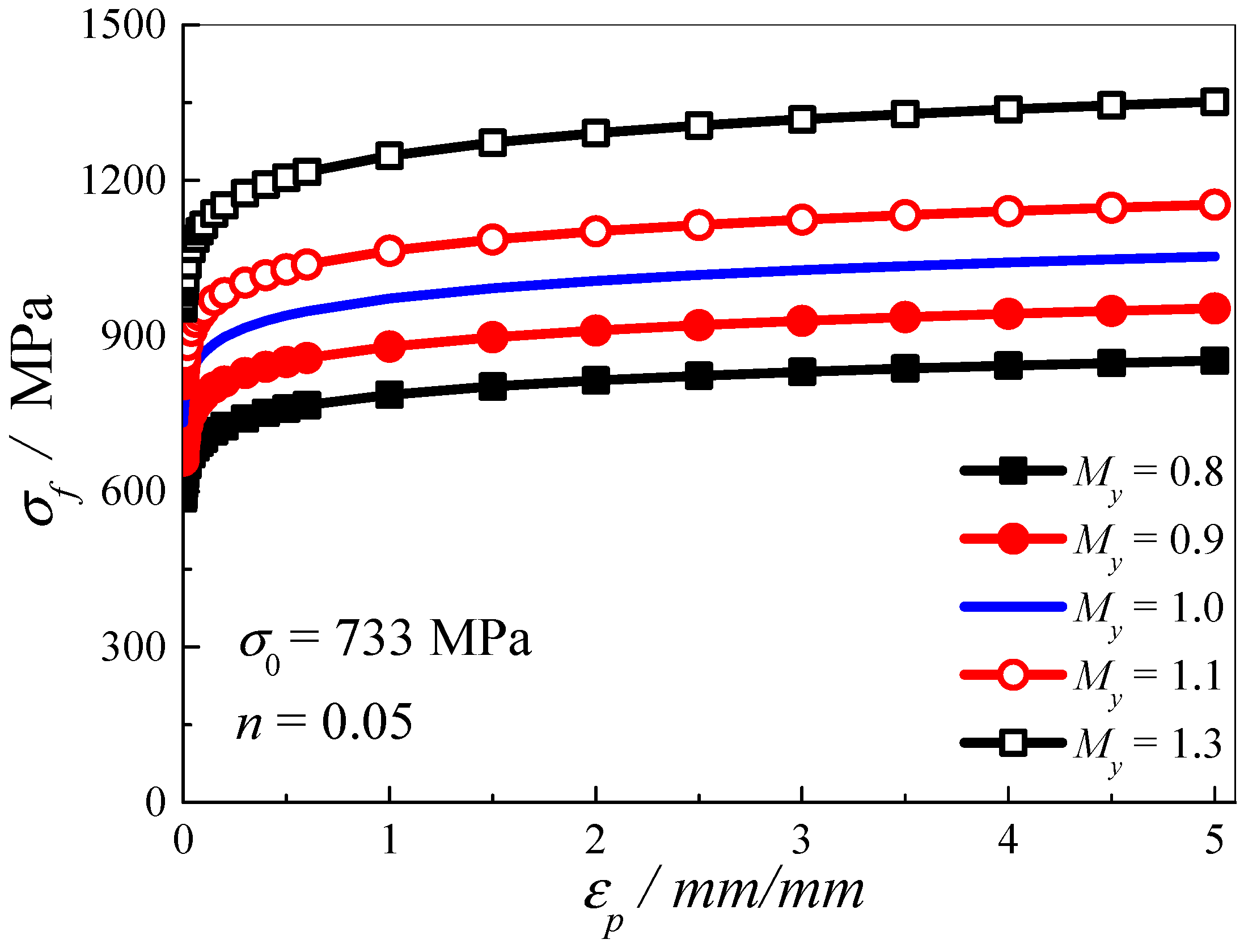

The propagation behavior of crack with different initiation position is affected by the constraint effect differences in dissimilar weld joints mechanical heterogeneity. The ductile fracture model of interface crack in dissimilar weld joints was built by adopting extended finite element method; the propagation characteristic of interface crack was summarized. The results indicate that the strength mismatch of materials at sides of interface will increase trend of crack advancing into the relative soft material which has lower yield strength and lower hardening exponent.

[1] R.S. Pathania, H.T. Tang and A.R. McIlree: in: CORROSION 2002, Denver, Colorado, (2002) NACE-02507.

[2] W. Bamford and J. Hall: In, 12th Int. Conference on Nucl. Eng., Vol. 1, Arlington, Virginia, USA, 2004, p.131.

[3] W.H. Bamford, J. Foster, K.R. Hsu, L. Tunon-Sanjur and A. Mcllree: In: Proc. 10th Int. Symp. on environmental degradation of Mats. in Nucl. power systems-water reactors. Houston: NACE (2001).

[4] L.Y. Zhao, H. Xue, K. Jiao and W. Tang: In: ICDMA (2013) p.207.

[5] F.W. Brust and P.M. Scott: In: ASME 2007 Pres. Ves. and Pip. conference, (2007) p.883.

[6] W. Ramberg and W.R. Osgood: Technical Note, No. 902. NACA, Washington, D. C, (1943).

[7] Y. Ueda, Y. Shi and S. Sun: Trans. JWRI. Vol. 26 (1997) p.133.

[8] Dassault Systèmes Simulia Corp., Abaqus analysis user's manual 6. 12 (2012).

Abaqus has always been a software of choice for modeling welding in various industries. This eSeminar will highlight the capabilities of the Abaqus Welding Interface (AWI), including some recent enhancements that make realistic simulation of the welding process possible in Abaqus.

The Abaqus Welding Interface (AWI) places an emphasis on the ease of weld model preparation and setup while supporting options and features that allow realistic predictions of quantities of interest such as distortion and residual stresses. A flux-based energy input option using the Goldak double ellipsoid model is now available for use with the AWI.

Another significant enhancement takes advantage of the new, strain-free element activation technique developed by SIMULIA R&D that has applicability in many important areas, including welding. This new technique improves pre-processing and analysis performance significantly for models of processes involving material deposition such as welding and additive manufacturing. As a result, strain-free element activation is no longer a step-dependent feature.

Abaqus Welding Interface Cracked Key

Presenter

Murali Pandheeradi, SIMULIA Director, Technical Sales, SIMULIA Great Lakes

Murali Pandheeradi is a Technical Sales Director and Technical Expert located in the Cleveland office of SIMULIA Great Lakes. He has been with the organization for over 13 years. Murali received his Masters in Engineering Mechanics from Indian Institute of Technology, Chennai (India) and PhD in Computational Mechanics from Rensselaer Polytechnic Institute, Troy, New York. He has over twenty years of experience in theoretical and applied FEA, and has co-authored publications and presentations in the field. His areas of technical expertise include advanced material models, composites, fracture and fatigue (including XFEM) and Abaqus User Subroutines.

To see the full replay, log on here to the SIMULIA Learning Community¹.